Beer Gas Solutions

|

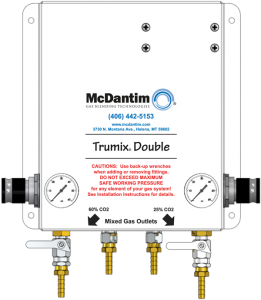

Gas blenders allow for on site blending of CO2 and nitrogen at the correct ratios with great accuracy. Using a gas blender allows beer to be dispensed when CO2 is inadequate without over-carbonating or flattening the beer. Higher pressure from a blender is ideal for temperature fluctuations and long remote runs. This world-renowned technology reduces waste while increasing sales due to quality assurance. | |

|

The all-new 2015 BeerBlast KPH – Mixed Gas Dispense System increases profits, eliminates over or under-carbonation and improves all around taste and draft beer quality. BeerBlast KPH models utilize state of the art technology that reduces operating costs and yields premium beverage grade nitrogen to preserve the brewer’s intended product quality. These lightweight and compact units are easy to install and are provided turn-key with a 60% CO2/ 40% N2 blend for lagers, 25% CO2 / 75% N2 blend for nitro-generated draft beers (i.e. Guinness) and 100% N2 for preserving open wine bottles, pushing wine or even coffee to the faucet. |